-

650 UHP Graphite Electrode

The 650mm UHP graphite electrode is the main conductor material used in electric furnace steelmaking and mineral furnace industry. This product uses P66 oil needle coke and liquid modified asphalt as the main raw materials. The main assessment indexes of large capacity electric furnace are consumption and breaking rate.

-

UHP 350mm Graphite Electrode

This is a 350mm diameter, ultra high power graphite electrode. China’s best quality graphite electrode. The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.

-

UHP 700mm Graphite Electrode

Grade:UHP

Applicable furnace: EAF

Length: 2100mm/2400mm/2700mm

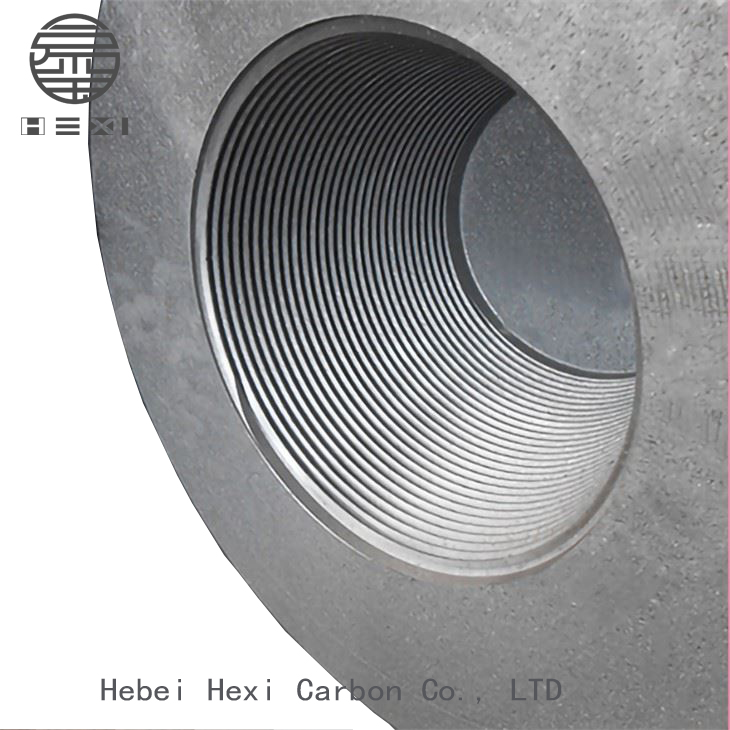

Nipple:3TPI/4TPI

Shipping Term: EXW/FOB/CIF

Payment: T/T; L/C

MOQ:10ton -

Ultra High Power Graphite Electrode

The main raw materials of ultra- high power graphite electrodes body are import oil needle coke. The production process include crushing, screening, Dosing,kneading,forming, baking,impregnation, second time baking, graphitization and machining. The raw material of nipples is import oil needle coke, the production process include three times impregnation and four times baking.

-

600 UHP graphite electrode

Grade:UHP

Applicable furnace: EAF

Length: 2100mm/2400mm/2700mm

Nipple:3TPI/4TPI

Shipping Term: EXW/FOB/CIF

Payment: T/T; L/C

MOQ:10ton -

UHP 550mm Graphite Electrode

This is a 550mm diameter, ultra high power graphite electrode. China’s best quality graphite electrode. The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.

-

UHP 500mm Graphite Electrode

Origin:China

Application: EAF or LF

Grade:UHP(Ultra High Power)

Nipple Thread:3TPI or 4TPI

Raw Material: Needle Coke

Delivery term:EXW, FOB, CIF, DAP -

UHP 450mm Graphite Electrode

This is a 450mm diameter, ultra high power graphite electrode. China’s best quality graphite electrode. The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.

-

400 UHP graphite electrode

Grade: Ultra High Power

Applicable furnace: EAF

Length: 1800mm/2100mm/2400mm

Nipple:3TPI/4TPI

Shipping Term: EXW/FOB/CIF -

300mm UHP Electrode

UHP 300mm graphite electrode is our main product. This product selects high quality needle coke, through forming, roasting, macerating, graphitization and mechanical processing and made, as high quality conductive materials for the arc furnaces