-

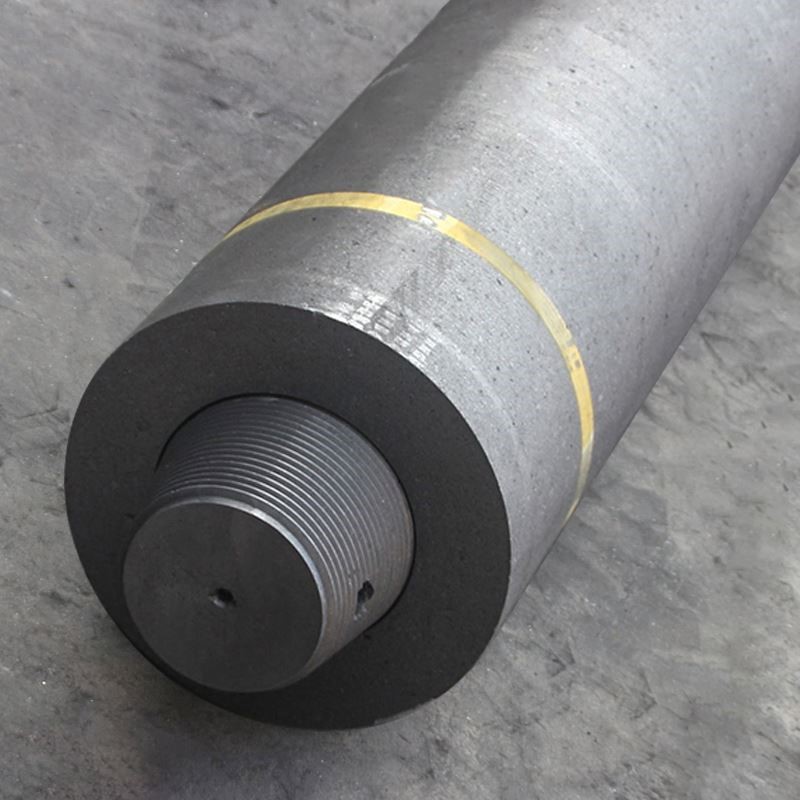

250HP graphite electrode

The diameter is 250mm, the length is 1800mm high power graphite electrode can be processed according to customer requirements, mainly used in steel arc furnace steelmaking.

-

high purity graphite rod(customized production)

The raw material of high purity graphite rod has large carbon content and small particle size than ordinary graphite rod, and the particle size is generally 20 nanometers to 100 nanometers. It is characterized by high strength, high density, high purity, fine particle size, high chemical stability, dense and uniform structure, high temperature conductivity, more wear-resistant than ordinary graphite rod, self-lubrication, easy processing and so on.

-

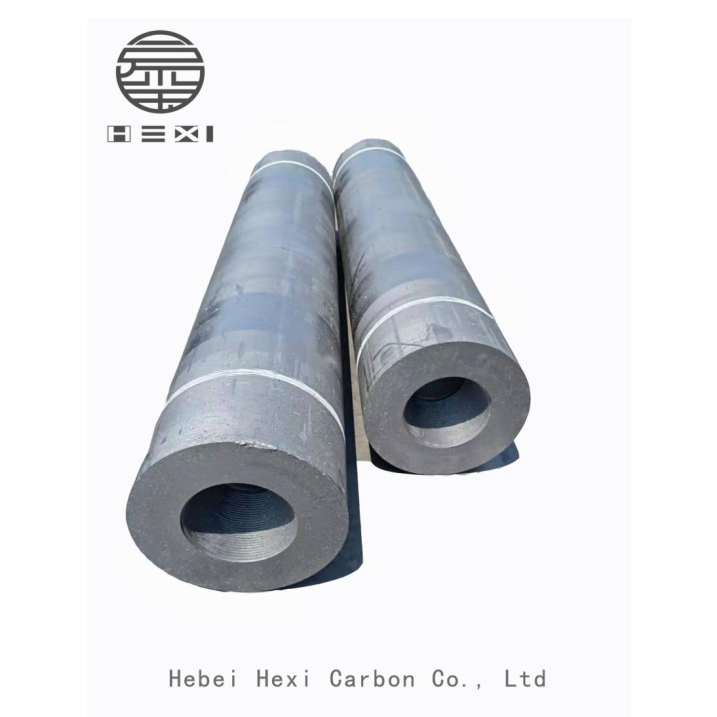

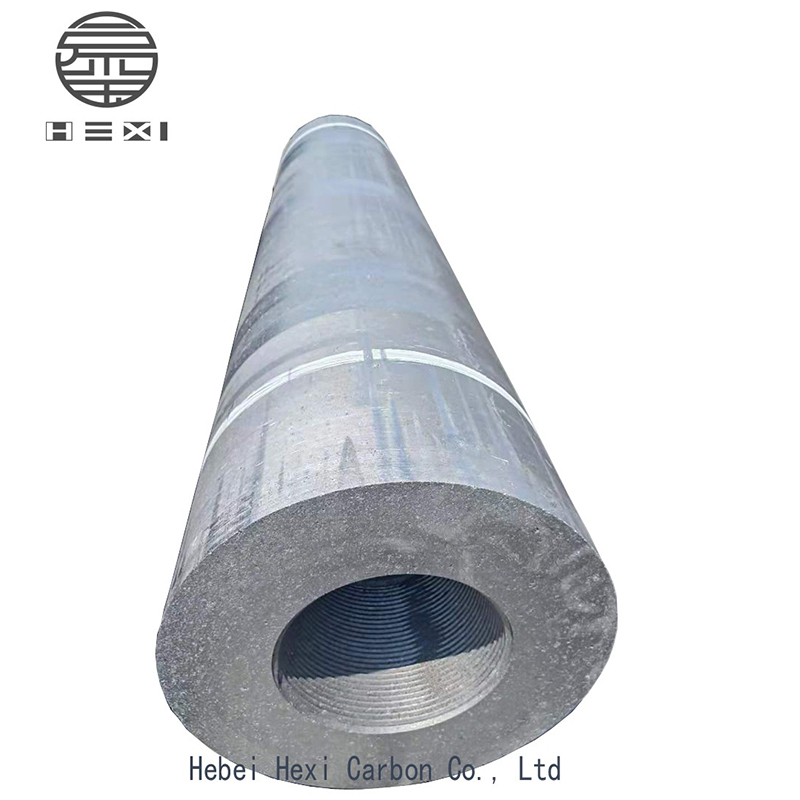

Extra Large Graphite Electrode

Large-size graphite electrodes, diameter 800-1400mm, electrodes and nipples can be customized according to customer requiremen

-

RP100 graphite electrode

The RP100 graphite electrode is a normal power diameter of 100mm

The diameter and length of the product can be customized according to customer requirements. -

600mm high power graphite electrode

This is a 600mm diameter, High power graphite electrode. China’s best quality graphite electrode.The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.

-

RP 450mm Graphite Electrode

The main raw material of graphite electrode production is petroleum coke. A small amount of asphalt coke can be added to ordinary power graphite electrode.

-

RP 400 Ordinary power graphite electrode

China’s best quality graphite electrode. 400 RP Graphite Electrode For LF Furnaces, they use more needle coke than their counterparts.Diameter range 300-600mm, length can be customized. Stock is available quickly.

-

RP 350 Ordinary power graphite electrode

The main manufacturing raw material of RP 350mm common power graphite electrode is petroleum coke, which can allow 13500-18000A current through, allowing the bearing capacity of less than 14 ~ 18A/cm² current density, which is generally used in steel making, silicon making, yellow phosphorus and other conventional power arc furnace.

-

RP 300 Ordinary power graphite electrode(1)

This is a 300mm diameter, ordinary power graphite electrode.China’s best quality graphite electrode. For LF Furnaces, they use more needle coke than their counterparts. We have a large stock and deliver goods quickly.

-

500mm high power graphite electrode

This is a 500mm diameter, High power graphite electrode. China’s best quality graphite electrode. The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.

-

450mm high power graphite electrod

This is a 450mm diameter, High power graphite electrode. China’s best quality graphite electrode.The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.

-

400mm high power graphite electrode

This is a 400mm diameter, High power graphite electrode. China’s best quality graphite electrode. The graphite electrodes produced by our factory are of good quality, stable performance, low consumption, complete specifications, rapid delivery and good service.