OEM/ODM China 2400mm Graphite Electrode - High Power Graphite electrode – Hexi

OEM/ODM China 2400mm Graphite Electrode - High Power Graphite electrode – Hexi Detail:

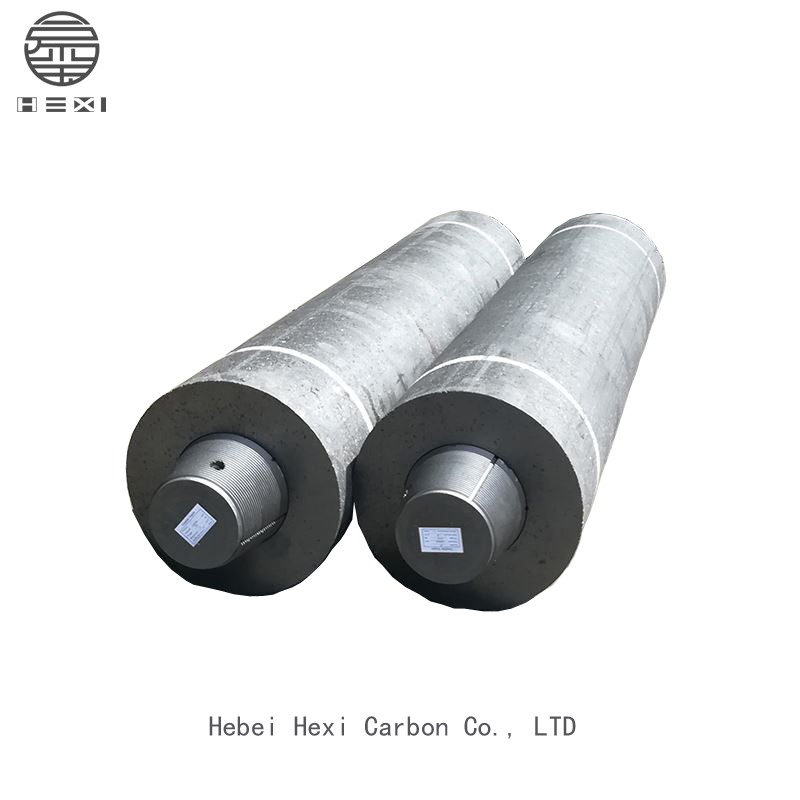

High-power graphite electrodes are produced from high-quality petroleum coke (or low-grade needle coke). The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing. The raw material of nipple is imported oil needle coke, and the production process includes twice dipping and three baking. Its physical and mechanical properties are higher than those of ordinary power graphite electrodes, such as lower resistivity and higher current density.

Used In Mine Electric Furnace

used in electric furnaces for the production of iron alloys, pure silicon, yellow phosphorus, calcium carbide and matte, characterized by the fact that the lower part of the conducting electrode is buried in the charge, so that in addition to the heat generated by the electric arc between the plate and the charge, heat is also produced by the resistance of the charge as the current passes through it.

The standard of high power graphite electrode and nipple

HP Graphite electrode Permissible current load

Hexi Carbon is a manufacturing company that produces, sells, exports and provides high-power graphite electrodes for wide application. Our company has been advocating the use of better materials and more advanced production technology to reduce the energy consumption and material cost of products. The high-power graphite electrode produced by our company has the characteristics of high density, low power consumption and high conductivity. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Transport of electrodes

When using forklift to transport stacked electrodes, care should be taken to avoid collision. Only one layer is allowed to be installed at a time, and attention should be paid to the balance and alignment to prevent slipping and breaking.

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto "High High quality, Competitive Rate, Fast Service" for OEM/ODM China 2400mm Graphite Electrode - High Power Graphite electrode – Hexi, The product will supply to all over the world, such as: Malaysia, Netherlands, Sierra Leone, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.