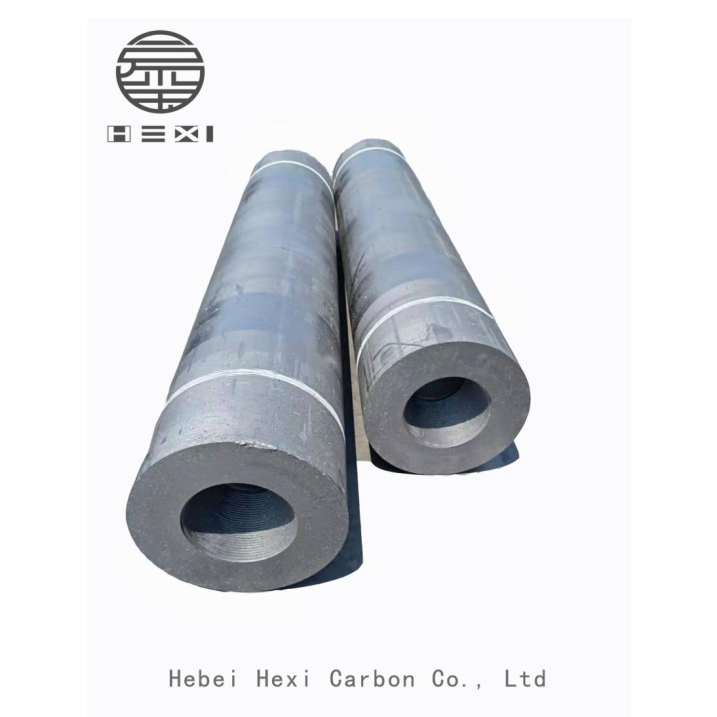

OEM Manufacturer Graphite Electrodes For Arc Furnaces - 400mm high power graphite electrode – Hexi

OEM Manufacturer Graphite Electrodes For Arc Furnaces - 400mm high power graphite electrode – Hexi Detail:

HP 400mm graphite electrode is mainly made of petroleum coke and needle coke. The allowable current is 21000-31000A, and the current density can be 16-24A/cm². Generally used for high-power electric arc furnace steelmaking.

The high-power graphite electrode is composed of high-quality petroleum coke, needle coke, coal pitch and other raw materials accounting for 66.88% of the cost. The production cycle exceeds 50 days, and the ultra-high power is up to 65 days. The production process includes calcination, batching, kneading, molding, baking, dipping, secondary baking, graphitization and processing.

|

高功率石墨电极和接头标准 High power graphite electrode and joint standard |

|||||

|

项目items |

单位unit |

公称直径 nominal diameter(mm) |

|||

|

200~400 |

450~550 |

550~700 |

|||

|

电阻率 specific resistance |

电极接头 electrode nipple |

μ Ω•m |

5.2~6.5 3.5~4.5 |

5.2~6.5 3.5~4.5 |

5.2~6.5 3.2~4.3 |

|

抗折强度 transverse strength |

电极接头 electrode nipple |

MPa |

≥11.0 ≥22.0 |

≥11.0 ≥22.0 |

≥10.0 ≥22.0 |

|

弹性模量 elastic modulus |

电极接头 electrode nipple |

GPa |

≤12.0 ≤15.0 |

≤12.0 ≤15.0 |

≤12.0 ≤15.0 |

|

灰分 ash content |

电极接头 electrode nipple |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

体积密度 bulk density |

电极接头 electrode nipple |

g/m³ |

1.68~1.73 1.78~1.83 |

1.68~1.73 1.78~1.83 |

1.68~1.72 1.78~1.83 |

|

热膨胀系数 (C.T.E) |

电极接头 electrode nipple |

10℃ |

≤2.0 ≤1.8 |

≤2.0 ≤1.8 |

≤2.0 ≤1.8 |

Hexi Carbon is a manufacturing company that produces, sells, exports and provides a wide range of high-power graphite electrodes. The high-power graphite electrodes produced by our company have models with diameters from 350mm to 700mm for you to choose, and other graphite electrode models you need can also be customized.

|

高功率石墨电极允许的电流负载 Allowable current load for high-power graphite electrodes |

|||||

|

公称直径 nominal diameter |

允许电流 allowable current |

公称直径 nominal diameter |

允许电流 allowable current |

||

|

mm |

A |

A/㎡ |

mm |

A |

A/㎡ |

|

200 |

6500~10000 |

18~25 |

450 |

25000~40000 |

15~24 |

|

250 |

8000~13000 |

17~27 |

500 |

30000~48000 |

15~24 |

|

300 |

13000~17500 |

17~24 |

550 |

34000~53000 |

14~22 |

|

350 |

17400~24000 |

17~24 |

600 |

38000~58000 |

13~21 |

|

400 |

21000~31000 |

16~24 |

700 |

45000~72000 |

12~19 |

Product detail pictures:

Related Product Guide:

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for OEM Manufacturer Graphite Electrodes For Arc Furnaces - 400mm high power graphite electrode – Hexi, The product will supply to all over the world, such as: Denmark, Switzerland, panama, We seriously promise that we provide all the customers with the best quality products, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.