OEM Factory for Graphite Electrode For Arc Furnaces - UHP 450mm Graphite Electrode – Hexi

OEM Factory for Graphite Electrode For Arc Furnaces - UHP 450mm Graphite Electrode – Hexi Detail:

Graphite electrodes play an important role in steelmaking industry, they are often used to melt the scrap in electric arc furnaces(abbreviated as EAF) . There are some key properties which determine the quality of electrode, what are they?

The coefficient of thermal expansion

(abbreviated as CTE) refers to a measure of the degree of expansion of a material after being heated, when the temperature increases by 1°C, it causes the expansion degree of solid material sample in a specific direction, which is called the linear expansion coefficient along that direction with unit 1×10-6/℃. Unless otherwise specified, the thermal expansion coefficient refers to the linear expansion coefficient. The CTE of the graphite electrode refers to the axial thermal expansion coefficient.

The bulk density

is the ratio of the mass of the graphite electrode to its volume, the unit is g/cm3. The larger the bulk density, the denser the electrode. Generally speaking, the larger the bulk density of the same type of electrode, the lower the electrical resistivity.

Elastic modulus

is an important aspect of mechanical properties, and it is an index to measure the elastic deformation ability of a material. Its unit is Gpa. Simply speaking, the greater the elastic modulus, the more brittle the material, and the smaller the elastic modulus, the softer the material.

The level of elastic modulus plays a comprehensive role in the use of electrodes. The higher the volume density of the product, the denser the elastic modulus is, but the poorer the product’s thermal shock resistance is, and the easier it is to generate cracks.

Physical Dimension

| DN | Actual Diameter | Nominallength and tolerance | |||||||

| Max | Min | 1800 | 2100 | 2400 | 2700 | ||||

| Standard | Short | Standard | Short | Standard | Short | Standard | Short | ||

| 300 | 307 | 302 | ±100 | -275 | ±125 | -275 | |||

| 350 | 357 | 352 | ±125 | -275 | |||||

| 400 | 409 | 403 | |||||||

| 450 | 460 | 454 | +200 -150 |

-300 | |||||

| 500 | 511 | 505 | |||||||

| 550 | 562 | 556 | |||||||

| 600 | 613 | 607 | |||||||

| 650 | 663 | 657 | |||||||

| 700 | 714 | 708 | |||||||

| 750 | 765 | 759 | |||||||

| 800 | 816 | 810 | |||||||

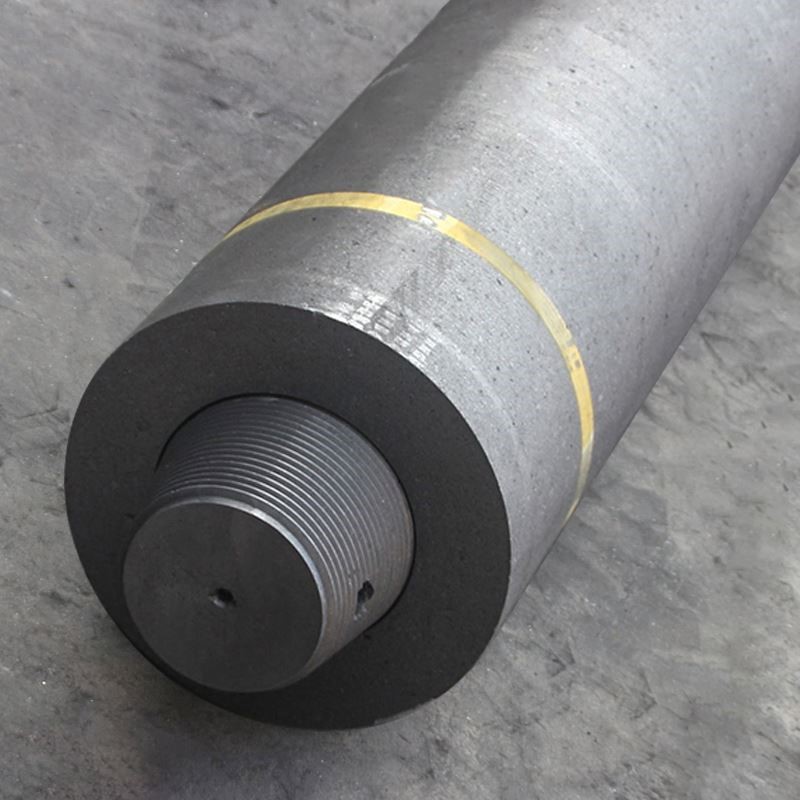

Product detail pictures:

Related Product Guide:

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for OEM Factory for Graphite Electrode For Arc Furnaces - UHP 450mm Graphite Electrode – Hexi, The product will supply to all over the world, such as: Kuala Lumpur, Lebanon, Algeria, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly