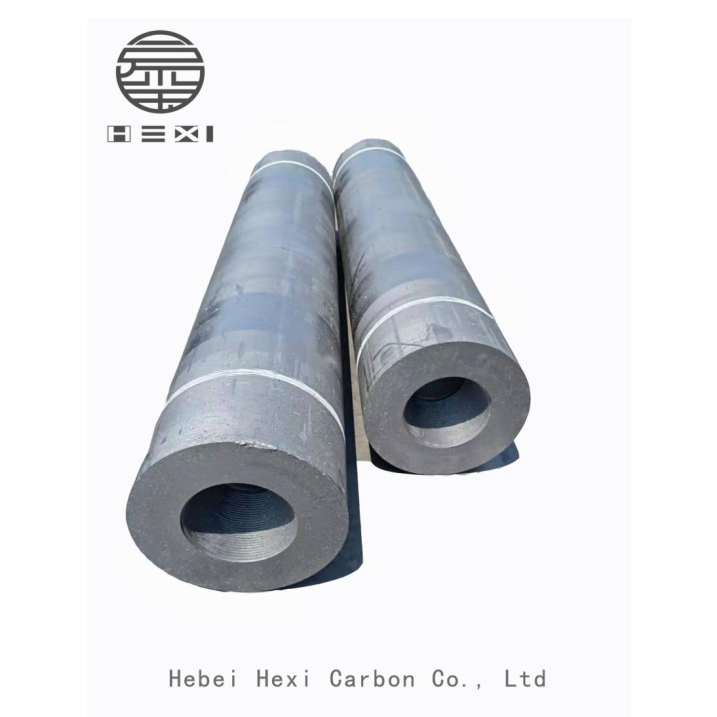

Manufacturing Companies for Graphite Electrodes For Arc Furnace - RP 350 Ordinary power graphite electrode – Hexi

Manufacturing Companies for Graphite Electrodes For Arc Furnace - RP 350 Ordinary power graphite electrode – Hexi Detail:

|

The products of Hexi have passed ISO9001 quality management system certification and obtained the export qualification of graphite electrode authorized by Chinese government. With good quality and excellent after-sales service, our products are in great demand in the world market.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Graphitization refers to the high temperature heat treatment process of transforming amorphous carbon into three-dimensional ordered planar hexagonal mesh laminated graphite by heating carbon products to 2300℃ or above in a high temperature electric furnace. The graphitization of carbon materials is carried out at a high temperature of 2300 ~ 3000℃. Because the combustion of fossil fuels is difficult to obtain such a high temperature, it can only be achieved by electric heating roasting in industry.

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Manufacturing Companies for Graphite Electrodes For Arc Furnace - RP 350 Ordinary power graphite electrode – Hexi, The product will supply to all over the world, such as: Las Vegas, Qatar, Malaysia, We have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we are looking forward to even greater cooperation with overseas customers based on mutual benefits. Please feel free to contact us for more details.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!