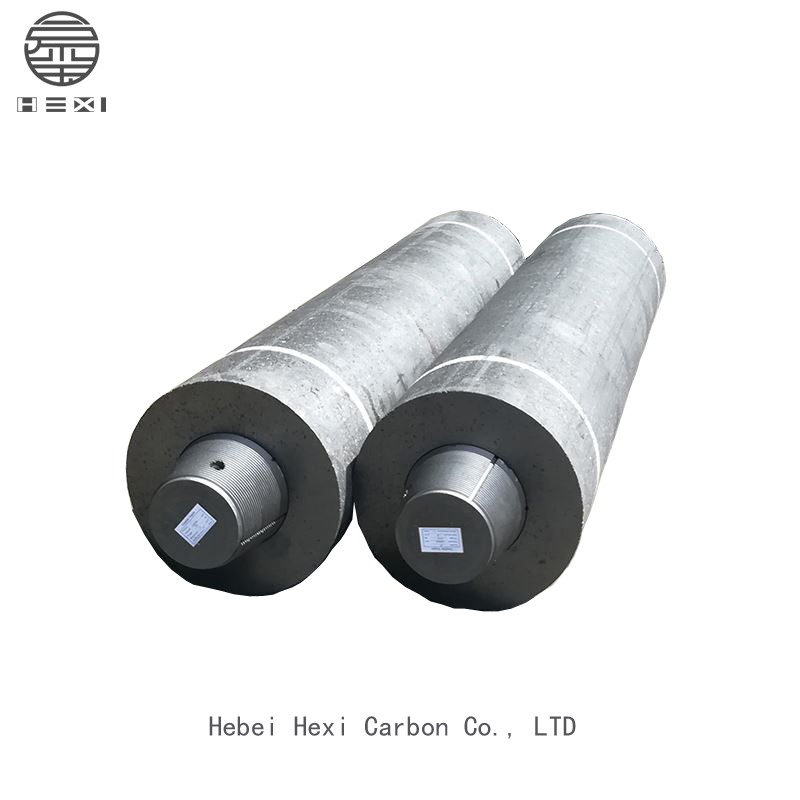

Manufacturer for Graphite Electrodes Cylinder - 500mm high power graphite electrode – Hexi

Manufacturer for Graphite Electrodes Cylinder - 500mm high power graphite electrode – Hexi Detail:

HP and UHP series of graphite electrode are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace.

HP 500mm graphite electrodes are very common in practice. There is a great demand in the world market. They are fit for electrical arc furnace, laddle furnace, and submerged arc furnace.

The loss of graphite electrodes in electric furnace steelmaking is very common, what are they and what is it related to? The following description is for your reference.

Physical loss

The physical loss of the electrode mainly refers to the end consumption and side consumption of the electrode, which is mainly caused by mechanical external force and electromagnetic force. It is concluded as follows

Looseness and breakage at the joint, cracking of the electrode and part of the thread of the joint falling off, which is caused by poor quality of the electrode itself,

In terms of equipment, improper electrode diameter selection, poor electrode holder, lifting and control devices;In terms of operation, large pieces of scrap collapses, hitting the electrode and poor connection between two electrodes

Chemical loss

Mainly refers to the consumption of the electrode surface, including the consumption of the electrode end and side. Generally speaking, the end consumption can reach 50% of the total electrode consumption, and the side consumption is about 40%. The larger the contact area between the electrode and the air, the greater the intensity of the oxidation reaction, and the consumption will increase accordingly.

Physical Dimension

|

Nominal Diameter |

Actual Diameter |

Nominal length and deviation |

||||||||

|

Max |

Min |

1800 |

2100 |

2400 |

2700 |

|||||

|

Standard |

Short |

Standard |

Short |

Standard |

Short |

Standard |

Short |

|||

|

500 |

511 |

505 |

±100 |

-275 |

±125 |

-275 |

±125 |

-275 |

+200/ -150 |

-300 |

Typical Properties

|

Properties |

Position |

Unit |

HP |

|

Specific Resistance |

Body |

μΩm |

5.8-6.6 |

|

Nipple |

4.2-5.0 |

||

|

Bending Strengh |

Body |

Mpa |

10.0-13.0 |

|

Nipple |

18.0-22.0 |

||

|

Young’s Modulus |

Body |

Gpa |

8.0-12.0 |

|

Nipple |

14.0-16.0 |

||

|

Bulk Density |

Body |

g/cm3 |

1.62-1.66 |

|

Nipple |

1.74-1.80 |

||

|

CTE(100-600°C) |

Body |

×10 -6/゚C |

1.6-1.9 |

|

Nipple |

1.1-1.4 |

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for Manufacturer for Graphite Electrodes Cylinder - 500mm high power graphite electrode – Hexi, The product will supply to all over the world, such as: European, Switzerland, Czech republic, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.