Leading Manufacturer for Graphite Electrode For Electric Arc Furnace - Regular Power Graphite Electrode – Hexi

Leading Manufacturer for Graphite Electrode For Electric Arc Furnace - Regular Power Graphite Electrode – Hexi Detail:

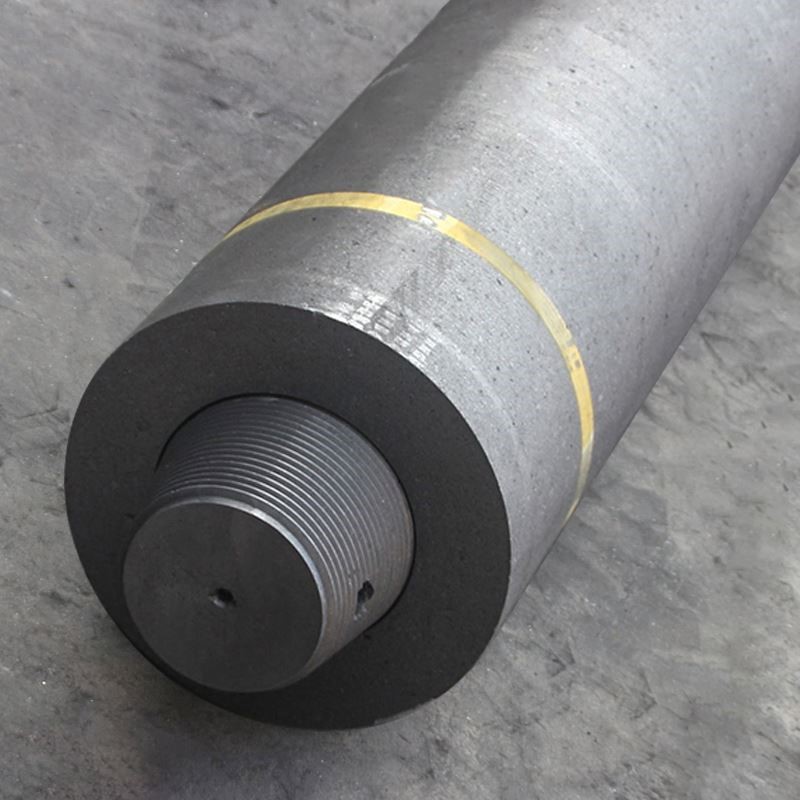

The main raw material of ordinary power graphite electrode body is high-quality petroleum coke, which is mainly used in electric arc furnace for steelmaking. The production process includes calcination, batching, kneading, forming, roasting, graphitization and machining. The raw materials of nipple are needle coke and high-quality petroleum coke, and the production process includes one impregnation and two roasting.

Hexi Carbon is a manufacturing company that produces, sells, exports and provides graphite electrodes for wide application.

Our ordinary power graphite electrode is mainly used for electric arc furnace steelmaking. Our price is fair and competitive. Our company promises free consultation and installation, free after-sales tracking and unconditional return of quality problems.

Used Of Resistance Furnace

the graphitizing furnace for graphite products used in the production of resistance furnaces, the melting furnace and production of technical glass, and the electric furnace for Silicon Carbide are resistance furnaces, and the material management in the furnace is both a heating resistance and a heat resistance, another subject to be heated up.

Processed Product

a large number of graphite electrode blanks are also used for processing various kinds of shaped products such as crucible, graphite boat, hot-pressing casting mould and heating body of vacuum electric furnace. It should also be noted that in the graphite materials including the graphite electrode, the graphite mold and the graphite crucible three kinds of high temperature composite materials, the graphite is easy to oxidize the combustion reaction under the high temperature, thus on the surface of the plastic material the carbon layer increases the porosity of the porous structure.

The standard of regular power graphite electrode and nipple

RP Graphite electrode Permissible current load

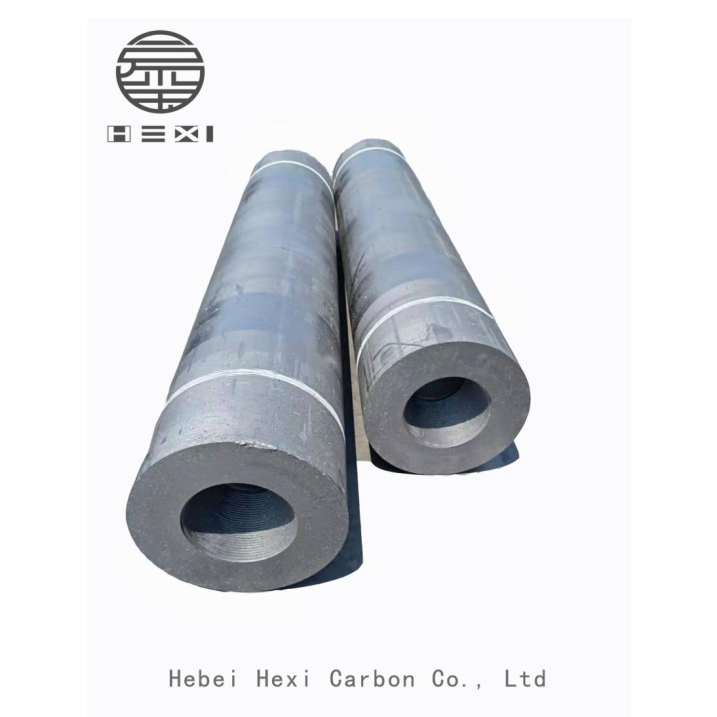

Product detail pictures:

Related Product Guide:

High-quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is constantly observed and pursued by our business for Leading Manufacturer for Graphite Electrode For Electric Arc Furnace - Regular Power Graphite Electrode – Hexi, The product will supply to all over the world, such as: Puerto Rico, Ireland, venezuela, Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!